Dy-nhn refractory mud is a kind of plastic refractory material containing silicon oxide. Under the action of high temperature liquid metal, it forms a unique SiC + C + SiO2 vitrified structure. The surface of the vitrified structure is smooth, the slag on the surface of liquid metal is difficult to adhere, and it is very easy to remove scum. It has outstanding resistance to surface spalling and corrosion. It can be used as a new material and repair material for hot metal transmission equipment.

Scope of application

The building materials of common cupola;

Repair materials and repair materials for all kinds of cast iron, molten steel ladle and turnover ladle;

Repair materials for taphole, cover and nozzle of water-cooled cupola;

The furnace construction materials and repair materials for the collar seal and taphole of coreless induction furnace.

Advantages and characteristics

High temperature resistance, excellent thermal strength;

Good thermal insulation performance;

Resistance to metal and slag erosion;

The slag on the surface of refractory mud is easy to clean.

It is easy to use and easy to operate.

Purpose of use

Hold high quality, high temperature liquid metal

Anti erosion, less scum, improve the quality of casting products

Long service life and low cost

Improve work efficiency, reduce the labor intensity of workers.

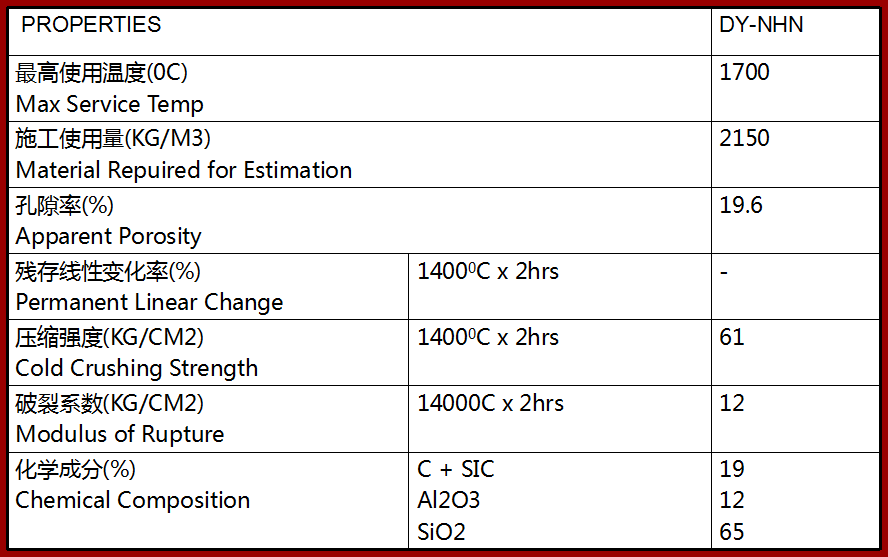

Specification parameters

Quality characteristics

Corrosion resistance

Due to the Glassification of the surface and the composite of SiC + C and SiO2 system with excellent corrosion resistance, the corrosion resistance is very good. Now it not only reduces the corrosion and adhesion, but also can easily remove the residual hot metal and slag

practicability

No need to use any tools, can be in any part of the construction, and the local repair is very easy, so it has good practicability

Security

Because the material with good safety performance in hot environment is selected, it has good safety at high temperature

Construction essentials

1. Scope of application

Dy-nhn refractory soil is a high silica refractory furnace wall repair material. It is made of selected silica raw materials and special inorganic compounds. For the convenience of use, the refractory soil is packed in plastic bags and then packed in cartons. This construction essentials is only applicable to dy-nhn produced by our company. According to the different site environment, we need to negotiate with our technical personnel to change the construction process

2. Product storage

1) Because dy - NHN contains special inorganic compounds, it will harden when contacting with air

2) Don't place it directly on the ground. Place it on thick cardboard or wooden board

3) If you want to stack in the field, use waterproof cloth and other covers to cover

3. Construction method

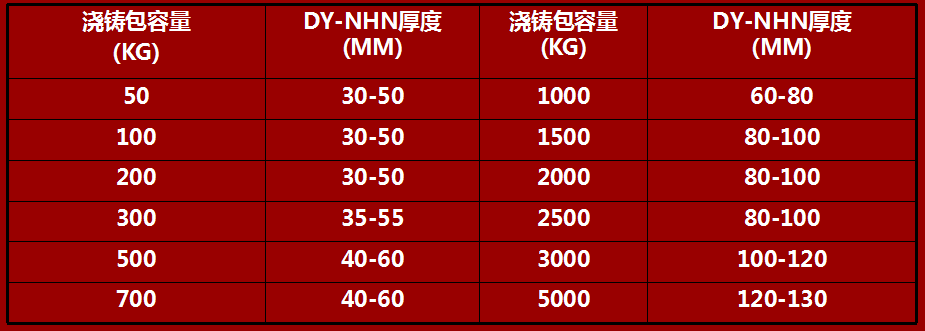

1) During the construction of the inner wall of the ladle, the thickness of dy-nhn varies according to the capacity of the ladle. In general, the thickness of dy-nhn of a 500kg ladle is 40-60mm. If the thickness of dy-nhn is too small, the outer steel plate will burn red, and the liquid metal may seep out, so the weak point is to make the repair thicker

2) The key to repair is to mix clay or plaster with proper water in the casting ladle to be repaired, and then apply it on the inner wall thinly. After that, take out the appropriate amount of dy-nhn by hand and directly apply it on it and tamp it with a hammer;

If the refractory mud is hard to repair due to water evaporation, it can be used after a little water infiltration (but do not use too much water, which will affect the service life);

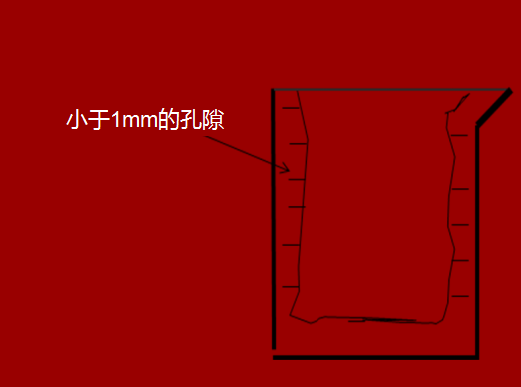

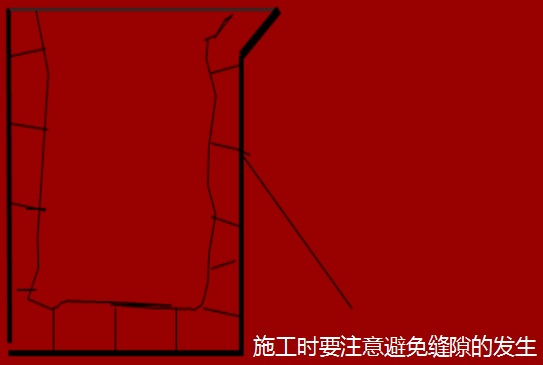

When repairing, if there is a gap in the joint of refractory mud, there will be the danger of metal liquid seepage, so it should be fully tamped

4. Drying and heating

1) After applying dy-nhn, the ladle should be fully preheated. First, dry the wood slowly for 3-5 hours, then bake it with a stove or a baking gun with a small fire, and slowly increase the firepower until the dy-nhn refractory soil turns red. According to this baking process, the service life of the ladle will be prolonged, so even if it is natural drying, it needs sufficient time to dry Dryness

Without sufficient preheating, the surface of dy-nhn will expand upward like bread when heated rapidly by furnace or baking gun. This phenomenon is caused by the swelling of water in dy-nhn, which makes the glassized surface arch out. Although this phenomenon can still be used, it will affect the service life

Therefore, heating should be done slowly before water is removed, and heating can be done quickly after 70-80% water is removed

In order to fully remove the moisture, the exhaust holes are tied with about 1 mm iron wire at the back and front of the casting package, so as to prevent the skin expansion during the drying process

2) There is no need to worry about cracks on the surface of dy-nhn due to gradual Glassification during natural drying. When the cracks are heated to above 800 ℃ with a baking gun, they will be bonded together, so there is no problem in filling the liquid metal. After the end of production, cracks will also appear due to the gradual cooling of the casting package. When they are used again, they will be re bonded due to the heating cracks, so there is no effect when they are used again

3) If the iron sheet outside the casting ladle turns red and a small amount of liquid metal seeps out during use, the same method can be used for local maintenance

4) After repairing the remaining dy-nhn, if it is directly placed in the air, it will harden. The remaining dy-nhn should be put back into the plastic bag and sealed for next use